Packaging Guidelines

Proper packaging is critical in the courier industry to ensure that items reach their destination safely, in optimal condition, and on time. Following best practices in packaging not only protects goods but also minimizes handling risks, reduces potential damage, and keeps customer satisfaction high.

1. Choose the Right Packaging Material: Use high-quality materials appropriate for the item’s size, weight, and fragility. Corrugated boxes are ideal for heavy or delicate items, while padded envelopes work well for smaller, durable items.

2. Wrap Fragile Items Individually: For fragile items, use bubble wrap, foam, or paper to cover each piece individually, preventing contact and reducing movement within the box. Place extra padding around them to further cushion against shocks.

Material

Choose 60-80microns hotmelt glue adhesive LDPE polybags

Use tamper evident polybags for high value items (Cost above Rs.7000)

3. Seal Properly: Use strong packing tape to secure all seams and edges, ensuring that the package won’t accidentally open during transit. Reinforce heavy boxes with extra tape, especially along the bottom.

4. Label Clearly: Labels should include the complete address, contact details, and a “Fragile” sticker if necessary. Additionally, avoid placing labels over seams or edges to prevent them from peeling.

5. Test for Durability: If possible, conduct a quick durability test by gently shaking the package to ensure items inside don’t shift. Properly packed packages withstand more stress, protecting your shipments and keeping clients happy.

Bubble Wrap Foam sheets

Packing an item involves leak proofing, cushioning, placing of the item and filling of the voids in the box. Enough cushioning needs to be provided to ensure no loads are transferred to the item.

Dimensions

Helps in selection of appropriate size of boxes/flyers. Minimize inventory & cost

Weight

Optimize for the minimum strength required for box. Ensures safety of item

Fragility

Helps select appropriate box strength. Helps in optimizing the cushioning.

Physical State

Identifies the need for any special requirements for the protection of item

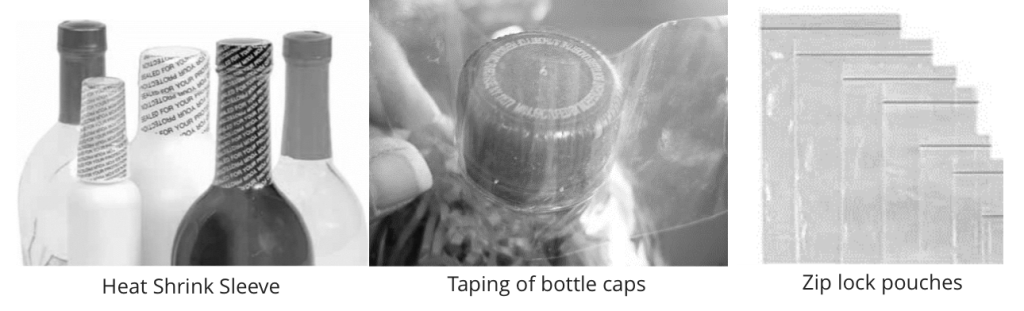

Leaking Proofing

Liquid products need to be made leak proof before cushioning or packing. Common leak proofing techniques are mentioned below.

Material

Heat shrink sleeves

Taping of bottle caps

Zip lock or leak proof pouches

Internal Packing Material vs Functionality